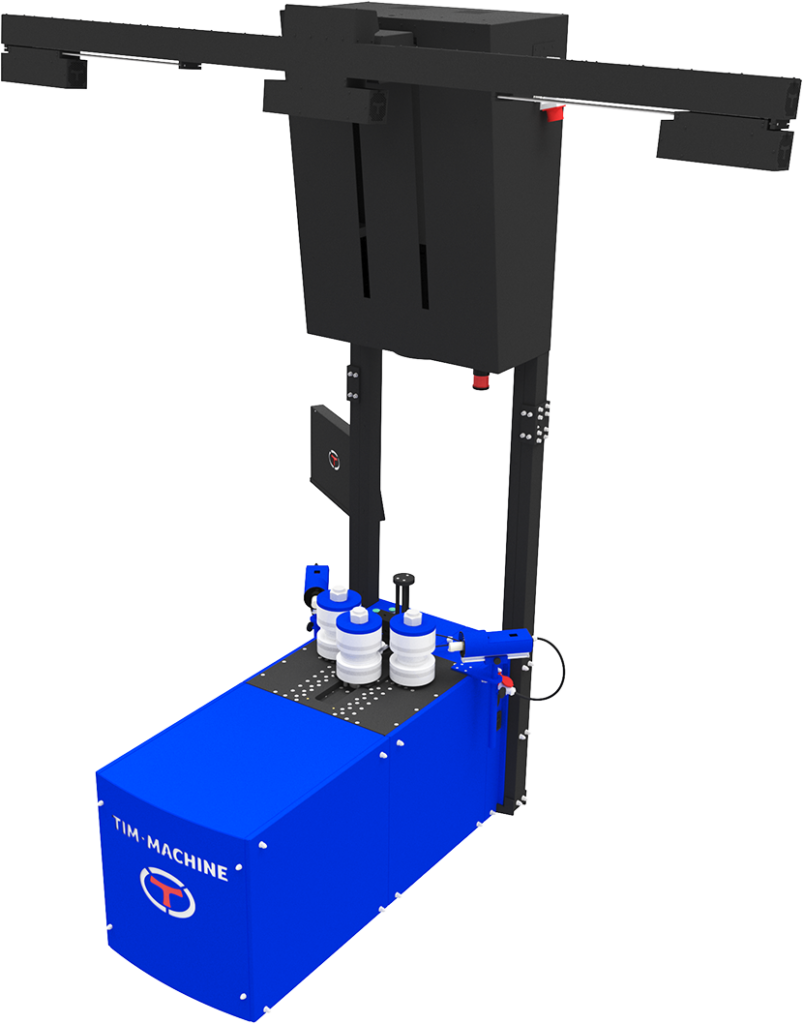

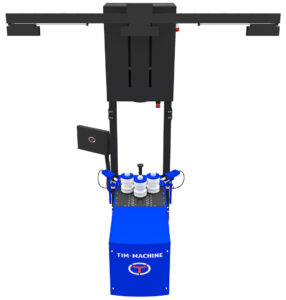

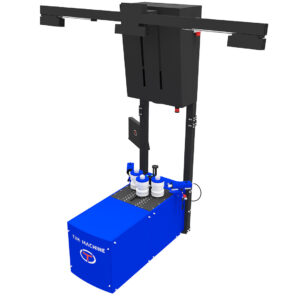

TIM-MACHINE

MODEL XS

CNC 3D

HOME » PROFILE BENDING MACHINES » MODEL XS SELECTION » MODEL XS CNC 3D BHP-AP

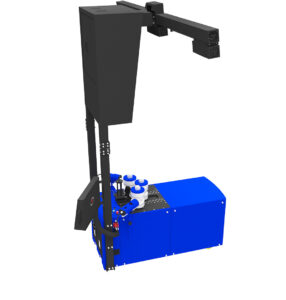

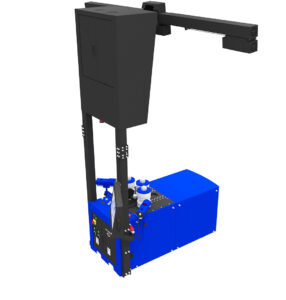

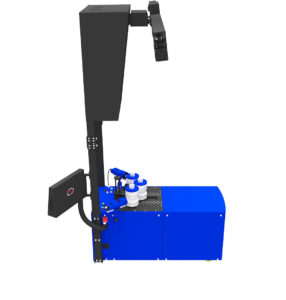

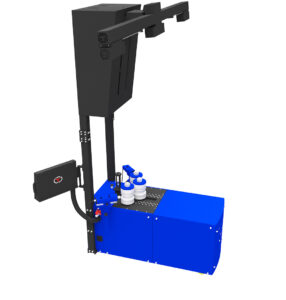

Profile bending machine

MODEL XS

CNC 3D BHP-AP

Basic equipment

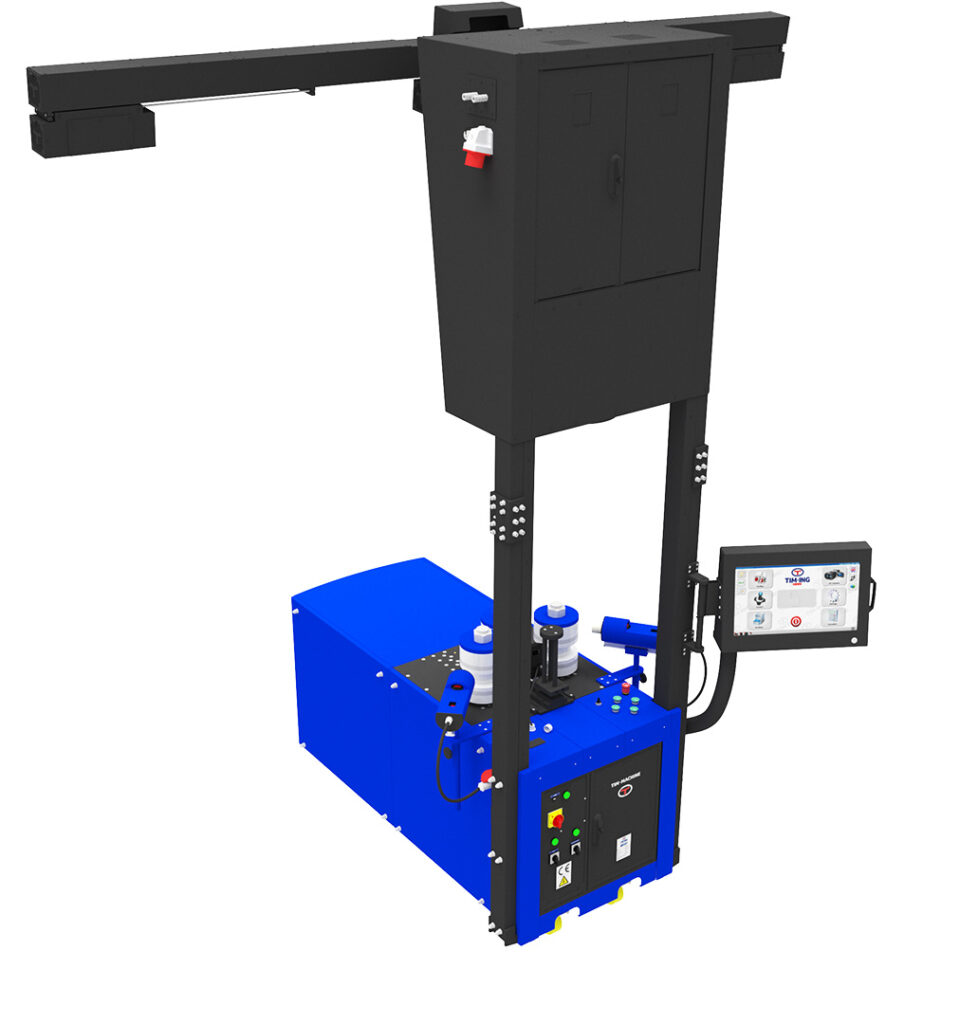

Three high precision

3D cameras with

automatic platform

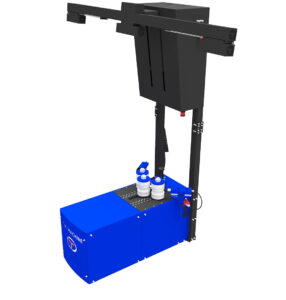

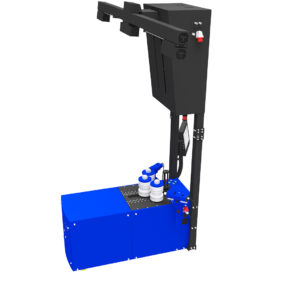

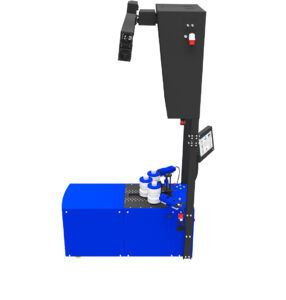

- This bending machine is equipped with one central high precision 3D camera and two additional high precision 3D cameras placed at both sides.

- This machine has high precision 3D cameras able to detect the profile width of 15 mm and larger than that.

- The advantage of these high precision 3D cameras is that they are having the possibility to detect white, light, narrow, raw and dark profiles.

- The machine can bend predefined complex arches that have one, two and three radii automatically in one process flow.

- The machine can bend arches from 350 mm to 2800 mm in the automatic mode.

- This machine model is equipped with a mechanical holder for the encoder that measures the distance.

- The machine is equipped with a laser device to ensure symmetrical arches.

- This Automatic platform can automatically mechanically zoom in and out with the 3D cameras automatically adjusting to the required arch dimensions.

- This will not only dramatically improve the sensing possibilities of the whole system but also ensure that the tiniest profiles, like glazing beads will be detected at the best possible accuracy.

- The system is able to lift up and down, expand or narrow the side cameras as well as tilt the whole camera system.

- Let me point out that the actual fixed position 3D camera system consists of one high precision central camera and two standard or high resolution side cameras.

- The automatic platform has two additional side cameras at high resolution.

- The results are impressive, enabling the whole new world of possibilities.

- This new system will minimize possible problems with detecting tiny glazing beads, detecting raw materials that reflect too much, or detecting dark painted profiles that don’t reflect anything.

- This new adaptive system will be able to sense larger arches as well as smaller arches at increased precision.

- Furthermore, it will be able to perform templates/patterns dimension and shape scanning (the software for this is still in the development).

- Even though the software for the scanning option is still in the development phase, the hardware that will support it, i.e., the 3D camera automatic platform needs to be provided.

- A retroactive 3D Camera platform upgrade will not be possible since the whole construction needs to be changed.

Profiles bending possibility

| Maximum profile height | 10 – 120 mm |

|---|---|

| Maximum profile width | 10 – 60 mm |

| Maximum profile (height + width) – Axis | 100 x 40 mm |

| Maximum profile (width + height) – Axis | 60 x 40 mm |

| Maximum profile length | Unlimited |

| Profile wall thickness | 1 – 3 mm |

Arches bending possibility

| Automatic bending arches with one radius | |

|---|---|

| Automatic bending arches with two radii | |

| Automatic bending arches with three radii | |

| Manual bending arches |

TECHNICAL SPECIFICATIONS

| Name | TIM-MACHINE |

|---|---|

| Model | MODEL XS |

| Type of machine | CNC 3D BHP-AP |

| Electric motor for X axis – back axle – 1 pcs | 5,5 KW |

| X axis – two back axles – max torque | 1290 Nm |

| Electric motor for X axis – middle axle – 1 pcs | 2,2 KW |

| X axis – middle axle – max torque per middle axle) | 1163 Nm |

| Electric motor for Y axis – threaded spindle – 1 pcs | 2.2 kW |

| Y axis – max torque per threaded spindle | 500 Nm |

| Number of propulsive axles | 3 |

| Dimensions | 2000 x 3500 x 3650mm |

| Weight | 1250 kg |

| Axle rotation speed | 0-20 rpm |

| Axle diameter | 70 mm |

| Axle height | 250 mm |

| Voltage | 3x380V~50 Hz |

| Warranty | 1 year |

| Country of origin | Serbia |

TIM-MACHINE

CNC 3D BHP-AP

MODEL XS